About Us

Fujian Sinyo Pipe Technology Co.,Ltd

Fujian Sinyo Pipe Technology Co., Ltd. was established in 2007 and is located in the demonstration park of the China-Indonesia "two countries and two parks" - Fuzhou New District Yuanhong Functional Zone, with unique geographical advantages. Sinyo Pipe is a national high-tech enterprise specializing in the manufacture of new plastic composite pipes.

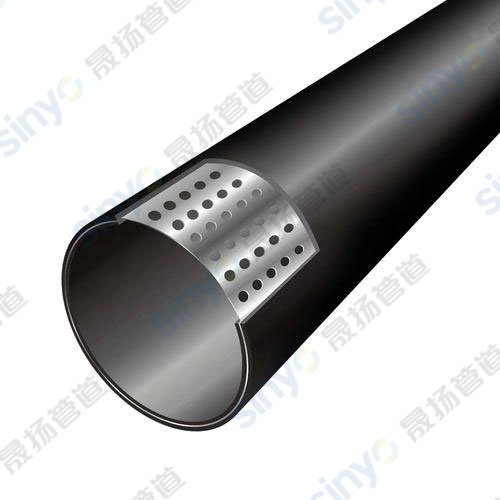

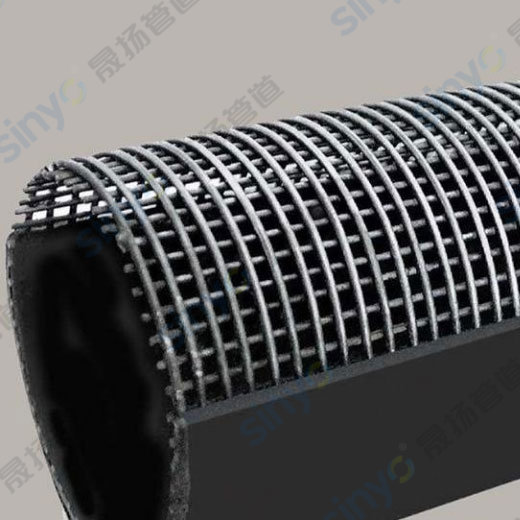

Innovation never stops. After years of continuous development and innovation, Sinyo pipe products have achieved diversified application fields, covering industrial chemical and pharmaceutical pipeline systems, municipal pipe network systems, special equipment pipe network systems, and marine aquaculture systems. "Sinyo" brand products mainly include: flame-retardant and anti-static perforated steel skeleton composite pipes, hot water perforated steel skeleton composite pipes, cold water perforated steel skeleton composite pipes, ultra-wear-resistant perforated steel skeleton composite pipes, PE/PVC/PP water supply and drainage pipes, double-wall corrugated pipes, gas pipes, mining pipes, PE reinforced spiral pipes (Kral pipes), steel strip reinforced polyethylene spiral corrugated pipes, steel-plastic composite pipes, deep-sea aquaculture pipes, deep-sea aquaculture platforms and other pipes and fittings.

Main Products

The company mainly produces PE/PP/PVC chemical, pharmaceutical, mining, water supply and drainage, gas, power, municipal and other new plastic pipes and steel-plastic composite pipe series products.

Why choose us?

Sinyo adheres to the business philosophy of quality as the foundation, customers as the core, and innovation as the soul, and aims to create value for customers, pursuing harmonious win-win results for enterprises, customers, and employees. Continuously improving the management level of the enterprise, with a higher starting point, faster speed, and better service, it stands in the forest of enterprises with a brand-new look.

View MoreQuality Control

With a CNAS certified laboratory, it has passed the ISO three major management systems and environmental mark certifications, and continuously introduces and digests international advanced technologies. In 2018, it was among the "Top 500 Chinese Enterprises" and was awarded the provincial-level unit of "Honoring Contracts and Keeping Promises", driving product iteration with hard-core technology.

Product System

Constructing a full range of PE/PP/PVC pipe matrix, covering eight major fields such as water supply, gas, and chemical industry. A breakthrough has been made in the manufacturing of HDPE water supply pipes with a diameter of Ф1200 and sewage pipes with a diameter of Ф2400, and the perforated steel belt composite pipe integrates the dual performance of metal and plastic, with technical indicators at the forefront of the industry.

Marketing Network

Branches have been set up in more than 10 core cities such as Beijing and Shanghai, constructing a three-dimensional service network of "headquarters + regions". Relying on a 200,000-ton production base, it achieves a nationwide 48-hour emergency response, providing customers with a full-cycle solution from production to construction.

Technical Equipment

Using advanced extrusion production lines from Germany, it provides a solid foundation for producing high-quality products, ensuring that product performance and quality are at the leading level in the industry, meeting the high standards of different fields for pipelines.

Product Display

Technology & Quality

Sinyo pipes take product technology and application innovation as the foundation of the enterprise, always keeping pace with the advanced technology of foreign plastic pipes, taking the development and application of new chemical building materials as the leading direction of the industry, and improving the overall market competitiveness of the enterprise through the introduction, learning, digestion, and absorption of advanced technologies.

You can contact us in the following ways

Email: sypipe@163.com

Tel: +86-0591-62838555

Blog&News

Company News

The company's product series is complete, covering PE/PP/PVC water supply, drainage, gas, mining, chemical, municipal, and power new plastic pipe series.

Industry Trends

The company mainly produces PE/PP/PVC chemical, pharmaceutical, mining, water supply and drainage, gas, power, municipal and other new plastic pipes and steel-plastic composite pipe series products.